Have a question?

Notified by email when this product becomes available

$1,029.15

You may also like

- Description

½ Ton Capacity Foundationless Floor Mounted Jib Crane

Features:

- Pulley: ½ Ton Capacity: Suitable for light to moderate lifting tasks

- No Foundation Design: No pre-poured foundation required, only bolted directly on existing concrete surfaces.

- 360°rotation: Full mobility to efficiently handle materials and height adjustable work.

- Robust Construction: Made from rolled steel I-beam and tapered flange. Designed for smooth trolley travel and long use.

- Versatile Use: Suitable for machining, assembly lines, and outdoor use (e.g. loading docks).

Product Description

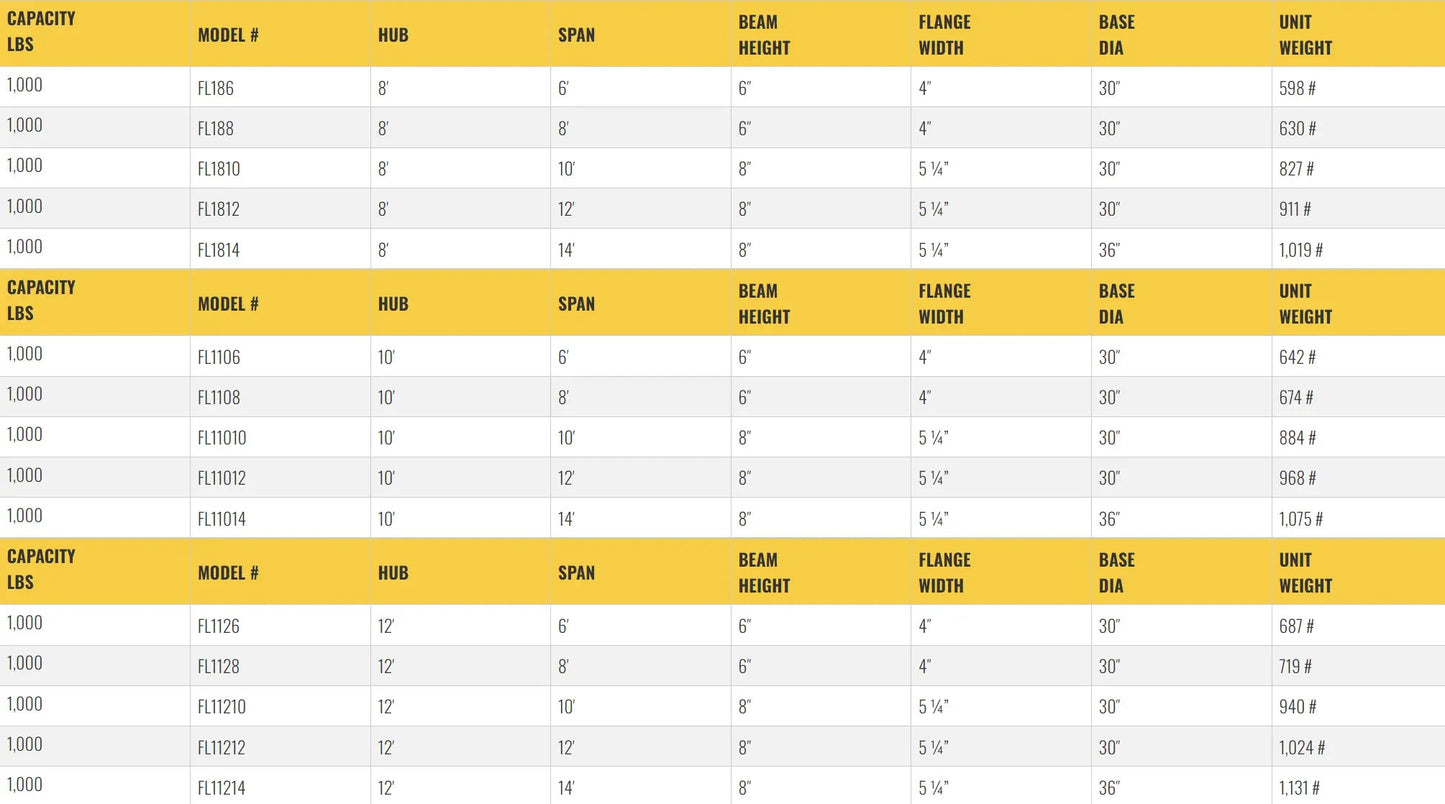

The All Lift Cranes Foundationless Floor Mounted Jib Crane FL-1000 Series is designed for the workplace that requires an overhead lifting solution but does not want the hassle and expense of pouring a foundation. This crane is the correct answer to your light-to-moderate lifting tasks as it has ½ ton lifting capacity. Best used in applications such as machining, assembly, and outdoor areas such as loading docks, or in conjunction with other jib cranes for staged coverage of large work areas.

No Foundation Required

FL-1000 Series’ most impressive feature is its foundationless design. Unlike a traditional jib crane which needs a poured concrete foundation, the FL186 can be installed directly onto an existing concrete surface. This makes it perfectly reasonable for businesses which do not wish to spend time or money pouring a foundation, or facilities which might need to relocate (the crane) to various locations. On the base you can choose from two different sizes; a 30” diameter base, which has a 26” bolt circle, or a larger 36” diameter base with a 32” bolt circle. They both come with 12 spaces with 1¼” holes for anchoring to the concrete.

Smooth and Safe Operation

When purchasing a FL-1000 Series jib crane, you'll be ready to run with a full support team to ensure smooth operations. A 360° rotating rolled steel I-beam cross section with a tapered flange, enables the trolley to run smoothly along the beam. Wrap it around your wrist, and it will alert you if you're too far from your device (it does track some movements, so it's way better than you'd expect at vibrating to let you know when you stray). This makes it safer in high-volume work settings where it can be moved accidentally resulting in an accident or product damage.

Versatile and Durable

The FL186 is one of the most versatile, with a minimum lift height of 8 feet and a maximum lift height of 12 feet, with a span between 6 feet and 14 feet. Such extendable measurements make the crane suitable for a broad spectrum of varying environments, whether they be compact locations or larger workspaces. Many industrial and commercial applications benefits from it up to a high level where it is used to lift and transport materials in manufacturing plants, assembly lines, and warehouses or similar settings.

Rugged construction designed to last for many years of service. It is made of steel construction so you use it on daily basis without worry about efficiency or reliability. Whether you use it in an indoor setup, or in an outdoor setting like loading docks, this crane’s extremely powerful construction that it will work effectively for most of its lifetime.

Further Performance Improvement Options

this Jib Crane have many other options available for added flexibility. Then these options are Tagline Kits with S-Hooks, Rotation Stops, Epoxy Anchor Kits, Bolt Pattern Templates. The crane is also configurable for outdoor or stainless steel applications.

Slightly more convenience can be provided by hoists and trolleys integrated with the crane plus an access Top Entry Collector Ring for smooth continuous rotation when an electric power cord is required. It allows smoother parcel movement without interrupts with crane movement while using this feature helps in streamlining the workflow.

Installation Requirements

The installation of the FL-1000 Series Jib Crane is simple and uncomplicated, provided the current concrete meets the required specifications. The concrete should be a minimum of 6 thick with a minimum 3,000 psi (5 bag mix) - 2,500 psi soil pressure. The place where the base plate of the crane will be accommodated should also be free from cracks, seams, joints walls, or delaminations, and the concrete shall be in good condition.

It is advisable for a local engineer to verify the foundation to confirm that the crane is moving safely and efficiently before installation.